Blocks and Mechanical Advantage

Introduction

This is the second part of a two part tutorial on mechanical systems made from blocks and line. The first part is HERE I will explore the mechanical advantage of various systems, and shows the general principles on how to set these systems up, including how to thread the line through the blocks, or reeve them. It will go from 1:1 to 6:1 with simple systems and up to 24:1 with cascaded systems. The second part will explore some more unusual systems.All block systems are comprised of a stationary part and a moving part. These terms are self explanatory. Most all tutorials on block systems show the fixed part at the top and the moving part, attached to some weight, at the bottom. In other words, they are systems that lift a load. It is left to the reader to realize these can be turned around and used to pull down. On a boat, the majority of block systems pull down. These include the mainsheet, vang, and Cunningham. For that reason, I am detailing systems that pull down as well as the more conventional diagrams that pull up. Some block systems pull sideways for example outhauls and reef systems. For those you can decide which drawing is most appropriate to your application.

Creating the diagram of a system that pulls up was a bit of a challenge. I needed something that represented an upward force and a weight of course always pulls down. What I decided to use was a super anti gravity filled balloon. This anti gravity gas pulls up with a force just as strong as the downward force supplied by the weight on the drawings. In use, you can replace my anti gravity gas balloon with your mast or sail.

Cascaded Systems

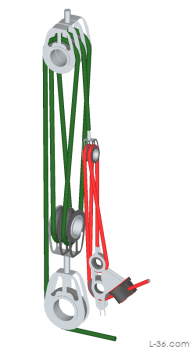

8 to 1 cascaded Vang System

A cascaded system has many advantages. It uses simpler blocks and is more likely to avoid twist and tilt issues. The disadvantage is that they take up a lot of room so are best for situations where there is a lot of space compared to the amount of motion you expect. A vang or backstay are examples of such applications. In the system pictured there are three 2:1 systems to the total advantage is 2 x 2 x 2 = 8. You can also cascade 2:1 with a 4:1 to get 8:1. There are a large number of useful possibilities.

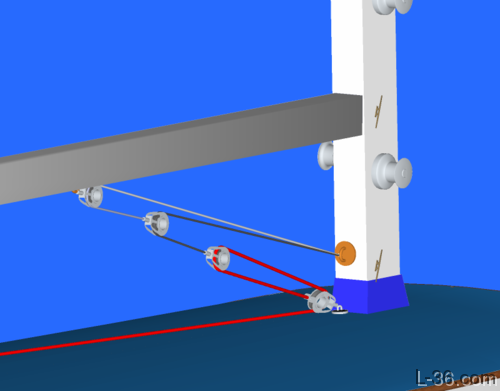

24:1 mainsheet fine course system

This mainsheet system is not only a cascade for the fine control, but feeds the other end of the line out through a turning block so that the major distance can be adjusted quickly with a 6:1 system. The fine is 4:1 so the net is 6 x 4 or 24 to 1.

Special or Unusual Reeving

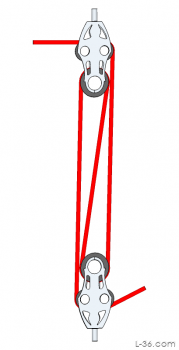

|

Sometimes special reeving makes since. In this case, when both ends needed to exit the fiddle blocks on opposite sides for a dual ended system, a simple reversing the direction of one of the sheaves did the trick. In this case, if you start with both ends and draw where you need them to go, and then continue with them to the next block, the reversal of the line between the two inner sheaves presents itself as the solution. |

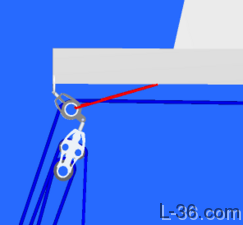

Capsizing Blocks

|

If you put a very unusual load on a block it can capsize and create a very high friction situation. I did this once by hanging a fiddle block on a single block. The line then fed out at 90 degrees from the single block. Consider that single block. It had 5 times the tension in the line pulling it down and one times the tension pulling it sideways. The result was that it capsized and tried to turn sideways. This happens because the force on the line going out at 90 degrees pulls on the sheave on the wrong side of the pivot point of the block. It is an extreme form of twist and not one that is particularly obvious. The solution was to provide some forward force to orient the single block in its natural position, at 45 degrees to both the incoming and outgoing lines. |

NOTICE: Some pages have affiliate links to Amazon. As an Amazon Associate, I earn from qualifying purchases. Please read website Cookie, Privacy, and Disclamers by clicking HERE. To contact me click HERE. For my YouTube page click HERE