Line and Rigging

Rings as Jib Leads

By Allen Edwards

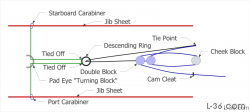

I have several articles on using rings as inhaulers and twings. This can be taken to extremes and the jib car can be eliminated and just the twing and inhauler used. It not only can be, that is how the TP-52 fleet is rigged. Here are some pictures to show it.

This is a picture I took a couple of years ago at the Big Boat Series in San Francisco of the TP-52 Mayham

Rings vs Eye-Splices

The sharp eyed reader will notice that the twing and inhauler on the TP-52 is made from an eye splice around a thimble. The corresponding gear in the other L-36.com articles use rings and luggage tags around the rings. The eye splices are clearly stronger than the line they are made from so clearly strong enough. On the other hand, the luggage tag is going to cause significant loss of strength. Starting with twice the strength of the line in the eye of the eye splice the strength is reduced by the loss of the luggage tag. I have not measured that loss but my guess is that it is between 25 and 50% strength remaining. Thus, the resultant could be as strong or half as strong as the line. With light loads, this should not be a problem but if you have small line or heavy loads, it could be an issue. With a safety factor and assuming a significant loss due to the know, I would want line to be 10x the load or 2x the rating of the jib sheet. Assuming a 60 degree off straight for the twing as shown in the TP-52 photo, that would be two loads at 30 degrees or about the same as the line load. That would mean you want the twing line in this case to be as strong as the sheet. As you can see from the photo, they are about the same diameter line so the eye around the thimble is appropriate.As with all strength issues, you need to ask what happens if it breaks. If an inhauler breaks, it may not be so important. If a twing breaks that is only there for off wind performance, it may also not be so important. On the other hand, if it is the only thing holding the jib sheet in place and serves as the normal fairlead, as is the case with the TP-52, it might be very important.

More Reading

|

For an article on calculating the friction involved in ring and line systems see THIS article. |

|

HERE is an article on a single line inhauler setup. |

| HERE is the article on jib sheet twings. |

NOTICE: Some pages have affiliate links to Amazon. As an Amazon Associate, I earn from qualifying purchases. Please read website Cookie, Privacy, and Disclamers by clicking HERE. To contact me click HERE. For my YouTube page click HERE